High Temperature Baghouse Pulse Bag Dust Collector Bag Filter System

The collector has advantages of blow and pulse injection either disadvantage of not enough energy in injection and filtering with ash removal at the same time. The dust bag is effective and increase adaption, Widely used in cement plant of crushing, packaging, library, clinker cooling machine and all kinds of mill dust collecting, system and gas dust collecting on metallurgical, chemical, mechanical and civil boiler flue

Characteristics:

1 .Dust removal efficiency can reach above 99.99 and dust emission can be controlled under 30 mg/NM

2.Can deal with high concentration of dust and dust collecting can be processing and recycling.

3.Advanced sealing measures and air leakage coefficient is less than 2%.

4.Special way of soot cleaning effectively, extend the service life of filter bag.

5.Stable performance, high degree of automation, simply maintenance and can be changed bag under non-stop machine.

- Porvoo

- China

- Information

- Video

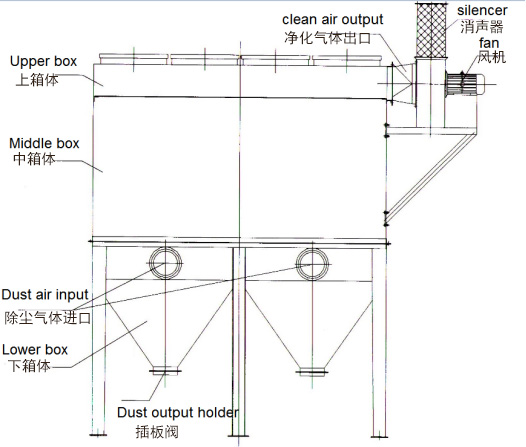

Working principle

Dust collecting process:

Dust air come into dust collector through air input, and big dust grain will drop into hopper, small and micron dust will be stopped outside filter bag surface, and clean air go through filter bag and be suctioned into atmosphere.

Dust removing process:

As filtration works continuously, dust outside filter bag surface increase continuously, then resistance of dust collecting increase, then certain room’s transferring valve will be closed and its filtration stop. Compressed air will go into filtration room in converse direction, and blow dust outside filter bag surface, then transferring valve will open, and filtration work again. Dust removing turns to next filtration room. Whole dust removing process take place alternately in all filtration rooms one by one.

Schematic diagram:

TECHNICAL PARAMETERS

| PROVOO32 SERIES | |||||

| Model | porvoo32-3 | porvoo32-4 | porvoo32-5 | porvoo32-6 | |

| Room(PC) | 3 | 4 | 5 | 6 | |

| Air volume(m3/h) | 5220-8700 | 6962-11604 | 11500-19200 | 13800-23000 | |

| Fiter area(m2) | 72 | 96 | 160 | 192 | |

| Qty of bags(PC) | 96 | 128 | 160 | 192 | |

| Size of bags(mm) | Φ130*1850 | Φ130*1850 | Φ130*2450 | Φ130*2450 | |

| Puse Valve | Size(in) | 1.5 | 1.5 | 2 | 2 |

| Qty(PC) | 3 | 4 | 5 | 6 | |

| Filtion velocity(m/min) | 1.2-2.0 | 1.2-2.0 | 1.2-2.0 | 1.2-2.0 | |

| Resistance(pa) | 1400-1700 | 1400-1700 | 1400-1700 | 1400-1700 | |

| Entrance dust concent concentration(g/Nm3) | <500 | <500 | <500 | <500 | |

| Exit dust concentration(mg/Nm3) | ≤30 | ≤30 | ≤30 | ≤30 | |

| Bearing pressure(pa) | <5000 | <5000 | <5000 | <5000 | |

| PROVOO60 SERIES | |||||

| Model | porvoo60-3 | porvoo60-4 | porvoo60-5 | porvoo60-6 | |

| Room(PC) | 3 | 4 | 5 | 6 | |

| Air volume(m3/h) | 12900-21500 | 17200-28500 | 21600-36000 | 25900-43200 | |

| Fiter area(m2) | 180 | 240 | 300 | 360 | |

| Qty of bags(PC) | 180 | 240 | 300 | 360 | |

| Size of bags(mm) | Φ130*2450 | Φ130*2450 | Φ130*2450 | Φ130*2450 | |

| Puse Valve | Size(in) | 2.5 | 2.5 | 2.5 | 2.5 |

| Qty(PC) | 6 | 6 | 6 | 6 | |

| Filtion velocity(m/min) | 1.2-2.0 | 1.2-2.0 | 1.2-2.0 | 1.2-2.0 | |

| Resistance(pa) | 1400-1700 | 1400-1700 | 1400-1700 | 1400-1700 | |

| Entrance dust concent concentration(g/Nm3) | <500 | <1000 | <1000 | <1000 | |

| Exit dust concentration(mg/Nm3) | ≤30 | ≤30 | ≤30 | ≤30 | |

| Bearing pressure(pa) | <5000 | <5000 | <5000 | <5000 | |