Efficient Solid-liquid Separation Equipment Rotory Press Filter

PRODUCT INTRODUCTION

Ceramic filter is an adcanced solid-liquid separation equipment in the world. Its core componect, ceramic filter plate, was successfully developed by Otto Kunpu Company of Finland. The aperture of ceramic filter plate is usually 1-5 micrions (the most commonly used is 1.5-2.0 microns). Such microppres can produce strong capilary action. When disc filter works,only liquid becomes filtrate through micropores under the action of vacuum pump, while solid and gas are blocked on the surface of filter plate to become filter cake, thus realizing solid-liquid separation.

The ceramic filter can be widely used for dewatering sand and gravel aggregates, coal, stone, ceramics, non-ferrous metal mines and other industries, and has a wide range of applications.

- Information

- Video

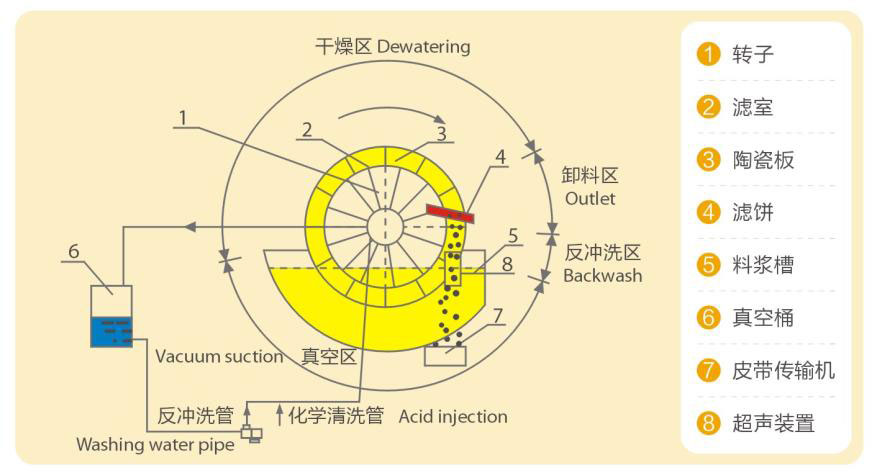

Working principle

Suction slurry

During the operation of the ceramic filter, the filter plate is immersed under the slurry level in the tank due to the vacuumizing effect, so that a solid particle accumulation layer is formed on the surface of the filter plate, and the liquid passes through the filter plate and is switched into the vacuum barrel by the distribution head.

Dry

When the filter plate with the accumulation layer sucked away from the slurry level, a filter cake is unloaded and sent to the required place by the belt converyor.

Unloading

The rotor continues to rotate to the position where the scraper is installed, so that the filter cake is unloaded and sent to the required place by the belt converyor.

Back flush

After the filter cake is removed, the operation position of the filter plate reaches the auto-coupling switching position to the flushing position opposite to the vacuumizing flow direction, thus forming the flushing funnction from the inside of the filter plate, removing particles blocked in the ceramic micropores, and then re-immersing into the slurry.

Deep cleaning

After the filter has been running for a long time, the filter plate can be completely washed, and the used backwash liquid can be added with chemical agents and co-operate with ultrasonic oscillation to maintain the efficient operation of the filter.

TECHNICAL PARAMETERS

| Model | WK-12 | WK-16 | WK-20 | WK-24 | WK-30 | WK-32 | WK-36 | WK-45 | WK-48 | WK-60 | WK-80 | WK-100 |

| Filter area | 12 | 16 | 20 | 24 | 30 | 32 | 36 | 45 | 48 | 60 | 80 | 100 |

| installed power(KW) | 12.15 | 16.25 | 18.75 | 18.75 | 18.75 | 18.75 | 24.55 | 24.55 | 24.55 | 35.9 | 48 | 60.8 |

| Power(KW) | 8.9 | 13 | 16 | 16 | 16 | 16 | 20 | 20 | 20 | 29 | 39 | 48.5 |

| quality | 3.5 | 5 | 6 | 7.5 | 9 | 9.5 | 10 | 12 | 12 | 15 | 18 | 20 |

| Long | 3600 | 4200 | 4700 | 5200 | 5800 | 6100 | 6400 | 7300 | 7300 | 7450 | 8750 | 8150 |

| Wide | 2800 | 2800 | 2800 | 3170 | 3170 | 3170 | 3200 | 3200 | 3200 | 3530 | 3768 | 3850 |

| High | 2100 | 2140 | 2140 | 2530 | 2530 | 2530 | 2590 | 2590 | 2590 | 2880 | 2880 | 3200 |